product description

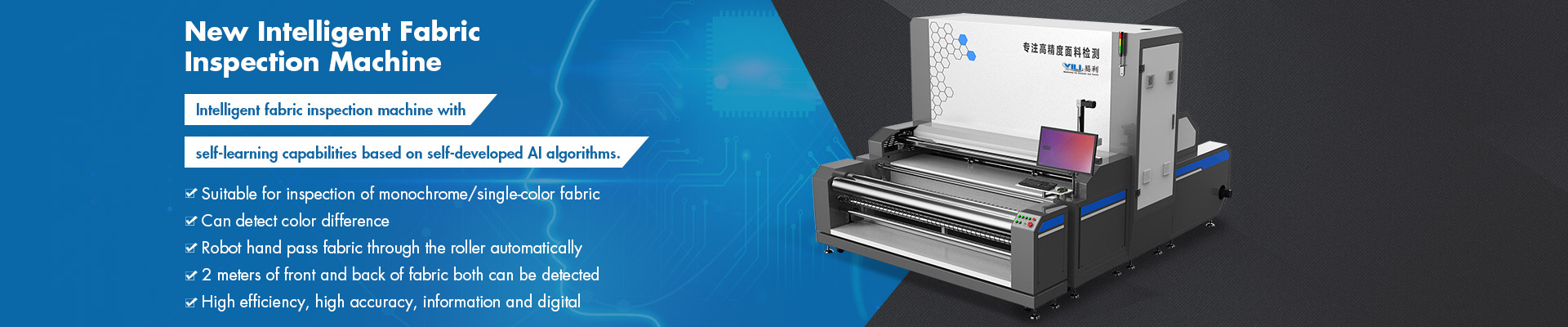

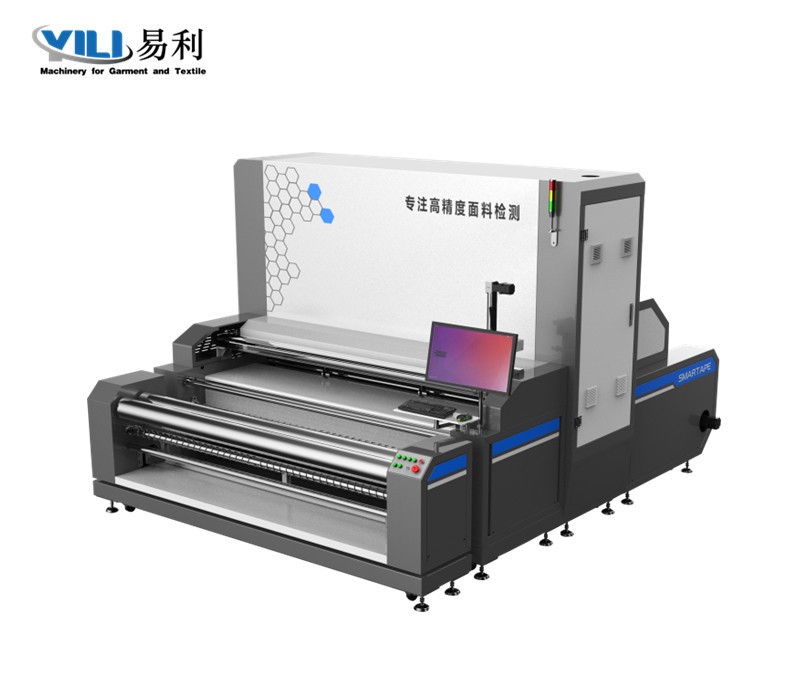

Highly automated intelligent textile inspection equipment

YL-2021AI

Inspection object: textile

Verifiable representative defects

Broken latitude, Oblique longitude, Broken latitude, wrinkle, breakage, knot, foreign body embedded and other kind of fabric defects

Main function and feature of fabric inspection

Three high pixel cameras are used to automatically inspected fabric surface defects, ensuring continuity and accuracy of inspection

Solve the problem of poor manual inspection effect, incomplete data and slow efficiency caused by various artificial and environmental factors such as fatigue and discursive of traditional manual inspection

Intelligent defects identification and marking: Sound and light alarm; Automatic saving the defect pictures; Automatic classify defects to ensure the validity of data; Automatic labeling ensure the position accurate

The machine works continuously with the fastest speed 30 meters per minute, relazing the high efficiency of inspection. An intelligent fabric inspection machines. Reduce the area of fabric inspection process and cost of labor

Independent reserch inspection software, with the exclusive right to use. Software function can be fully customized according to customer requirments

Other feature

Complete fabric width defect information statistics: each roll material has its complete defect image, location distribution, defect quantity statistics and other information.

After inspection, the grading system is automatically adopted, according to the international standard four-point system, effectively control the fabric quantity

Can connect with network to upload reports, the management can check the fabric data at any time

Use the imported control electrical appliances and control system(PLC)

Normal function: Fabric inspection, fabric rolling, measurment, automatic edge alignment

Machine efficiency

Fully intelligent fabric quality defect by camera vision

Inspection efficiency, data accuracy, fabric value maximization, inspection cost minimization

Attached defect statistics system, storage system, etc

Machine value maximization

4people, 400%, 400%, 24months

Labor, Production capacity to be improved, Inspection accuracy to be improved, Cost return cycle

| Technical specification | ||||||

| Model | YL-2021AI | |||||

| Voltage | 220V, 50Hz | |||||

| Max. diameter of one roll fabric | 40cm | |||||

| Max. fabric working width | 2100mm | |||||

| Working speed | 0-40m/min | |||||

| Power | 4kw | |||||

Technical indicators

Inspection time: single time inspection (Option:double time inspection with 6 cameras )

Inspection accuracy: 0.5mm

Sampling inspected qualified rate: not less than 90%

Defect mark: stop working and stick label (Optional: ink jet mark, no need stop working )

Defect recognition tips: automatic sound and light alarm, software record defect location, quantity and size

Defect information: record the number of defect meters, horizontal position, image information, etc

With product phase positioning detection function, beyond the error range can automatically identify and remove

Product defect library can be added

With anti-jitter function, the camera system ivision range s larger than the material size.